# Style AI: Revolutionizing Design with Artificial Intelligence

Artificial intelligence is reshaping industries worldwide, and design is no exception. **Style AI** represents a groundbreaking fusion of creativity and technology, offering unprecedented capabilities for designers and brands. This transformative technology leverages machine learning to analyze trends, generate concepts, and streamline workflows—ushering in a new era of efficiency and innovation.

## **Core Capabilities and Features**

### **Automated Trend Analysis**

Style AI processes vast datasets from fashion runways, social media, and market trends to identify emerging styles. It delivers actionable insights, helping designers stay ahead of the curve.

### **Personalized Design Suggestions**

By learning user preferences and historical data, the AI offers tailored recommendations, reducing guesswork and enhancing creativity.

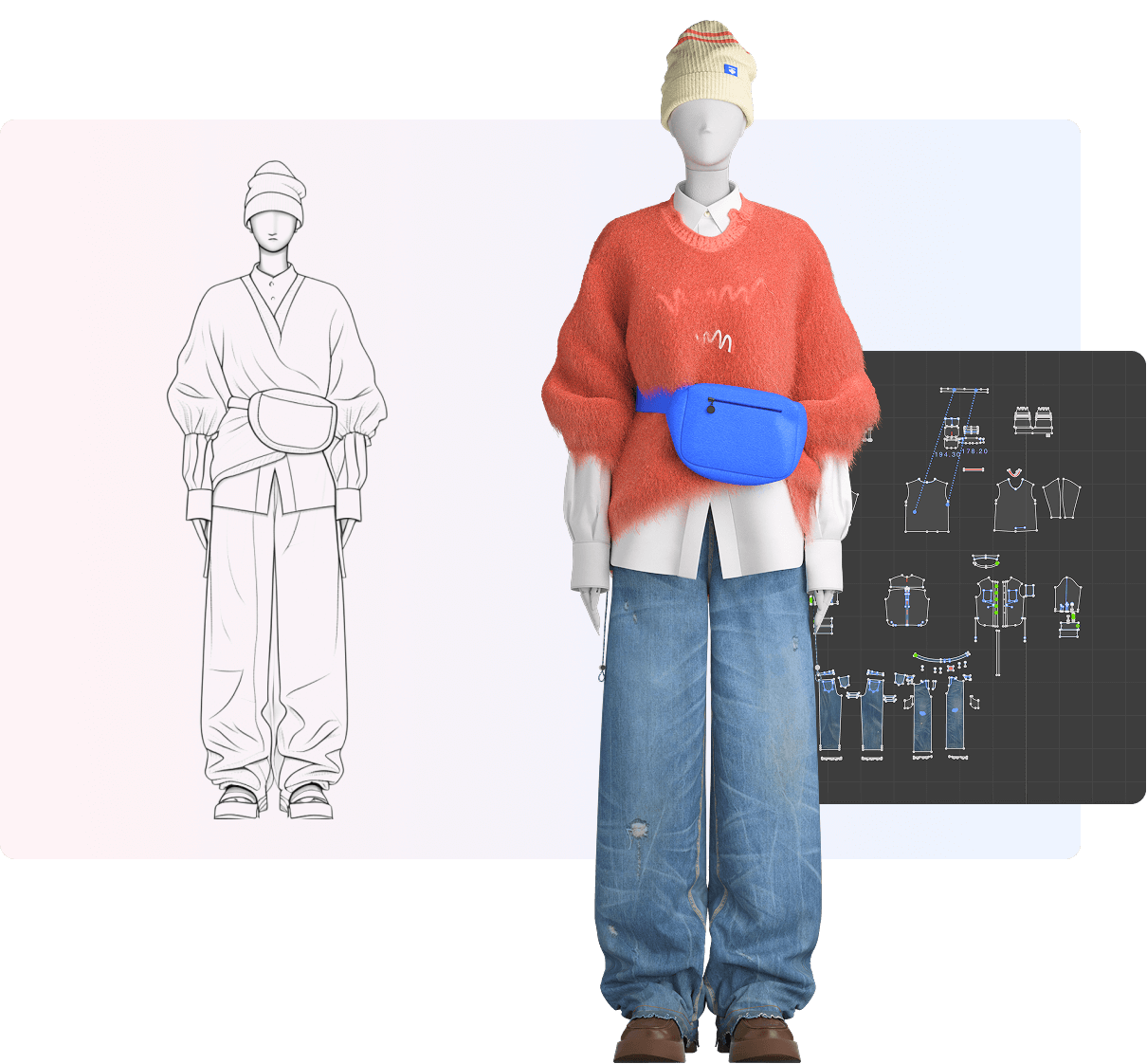

### **Rapid Prototyping**

Generate mockups and prototypes in minutes instead of weeks. This accelerates iteration and reduces time-to-market for new collections.

## **Frequently Asked Questions**

**How does Style AI improve design accuracy?**

It uses deep learning algorithms to ensure color, pattern, and style recommendations align with current trends and user preferences.

**Is Style AI suitable for small businesses?**

Absolutely! Its scalable solutions cater to independent designers and large enterprises alike.

**Can it integrate with existing tools?**

Yes, it supports compatibility with major design software like Adobe Illustrator and CLO3D.

## **Transform Your Design Process Today**

Ready to embrace the future of design? Explore the power of style ai and revolutionize your creative workflow. From concept to customer, achieve faster, smarter, and more inspired results.

**Start your free trial now and experience the difference!**