Factors Affecting the Service Life of Geotextiles: Durability and Maintenance

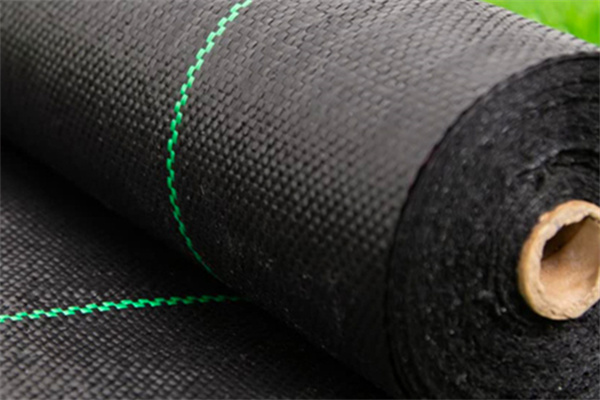

Geotextiles are widely used in civil engineering and construction projects for their ability to enhance soil stability, improve drainage, and provide erosion control. They play a crucial role in applications such as road construction, foundation stabilization, and landscaping. However, the service life of geotextiles is influenced by several factors, including material composition, environmental conditions, and maintenance practices. Understanding these factors is essential for maximizing the longevity and performance of geotextiles in various applications.

1. Material Composition and Quality

The durability of geotextiles begins with the material they are made from. Geotextiles are typically produced from synthetic materials such as polypropylene, polyester, or polyethylene. Each of these materials has different properties, such as resistance to UV radiation, chemicals, and temperature fluctuations, which directly affect their lifespan.

Polypropylene is commonly used for its resistance to chemical degradation and ability to perform well in high-strength applications.

Polyester geotextiles are favored for their strength and resistance to UV radiation, making them suitable for applications exposed to sunlight.

Polyethylene, while less common, is highly resistant to abrasion and is often used for applications involving extreme conditions.

When purchasing geotextiles, it’s important to consider the specific requirements of the project and choose materials that will withstand the environmental conditions to which they will be exposed. For those looking for affordable solutions, it’s possible to buy geotextile from reputable sources that offer good quality products at competitive prices.

2. Exposure to Environmental Conditions

Environmental factors play a significant role in the degradation of geotextiles. The primary factors that affect the service life of geotextiles include:

UV Radiation:

Prolonged exposure to ultraviolet (UV) rays can break down the chemical structure of geotextiles, particularly those made from polypropylene and polyethylene. UV degradation can lead to the weakening of fibers and eventual failure of the geotextile. To mitigate this, manufacturers often add UV stabilizers to their products, but over time, these additives may lose effectiveness.

Temperature Fluctuations:

Geotextiles that experience extreme temperature changes, such as those in hot climates or areas with harsh winters, are more likely to suffer from physical wear and tear. High temperatures can cause the materials to become brittle, while freezing temperatures can make them more prone to cracking.

Chemical Exposure:

Geotextiles used in soil stabilization or drainage systems may come into contact with various chemicals, such as fertilizers, pesticides, or industrial effluents. The composition of the geotextile determines its resistance to chemical degradation. Polyester-based geotextiles are generally more resistant to chemicals than polypropylene ones, making them a better choice for chemically aggressive environments.

Mechanical Stress:

Geotextiles are subject to mechanical stress, especially in road construction and other high-load applications. Over time, repeated loading and unloading can cause the fibers in the geotextile to break down. Proper installation and maintenance can help alleviate some of the stress on the material, but eventually, wear and tear will take its toll.

In regions with extreme conditions, it’s important to select a geotextile that has been specifically designed to withstand the local environment. For instance, if you’re working in a location with high UV radiation, it might be best to purchase geotextiles that are treated with UV inhibitors to increase their lifespan.

3. Proper Installation Practices

The service life of geotextiles is also highly dependent on proper installation techniques. Incorrect installation can result in premature failure of the geotextile, regardless of the quality of the material. Common installation issues include:

Overstretching:

When geotextiles are overstretched during installation, they may lose their strength and fail prematurely. It’s essential to install the material without over-tensioning it to ensure optimal performance.

Improper Overlap:

Geotextiles are often used in layered systems, where sections of the material are overlapped to ensure continuous coverage. If the overlap is insufficient or improperly aligned, the geotextile may fail under load.

Poor Anchoring:

Geotextiles must be properly anchored to prevent movement or displacement over time. Improper anchoring can result in the material shifting out of place, causing it to lose its effectiveness in providing stability or filtration.

Hiring a professional with expertise in geotextile installation can help prevent these issues and ensure that the material performs as expected over its service life.

4. Regular Maintenance and Inspections

Regular maintenance and inspections are vital for extending the lifespan of geotextiles, especially in projects where the material is exposed to harsh conditions. Some key maintenance practices include:

Cleaning:

Geotextiles used in drainage applications can become clogged with debris, silt, or sediment. This can reduce their filtration efficiency and lead to the failure of the entire system. Regular cleaning of geotextiles, especially those used in erosion control or drainage systems, is essential to maintain performance.

Repairs:

If geotextiles become damaged due to mechanical stress, punctures, or environmental factors, they should be promptly repaired or replaced. Small holes or tears in the material can compromise its integrity and lead to larger issues down the line.

Monitoring:

Regular monitoring of geotextiles in use can help detect signs of wear early, allowing for timely intervention before the material fails completely. Signs to watch for include visible degradation, stretching, or shifting of the material.

For those looking to replace worn-out geotextiles or add more to their existing systems, finding a cheap geotextile manufacturer who offers reliable and durable products can make a significant difference in reducing overall project costs.

5. Conclusion

The service life of geotextiles is influenced by various factors, including material composition, exposure to environmental conditions, installation practices, and ongoing maintenance. By understanding these factors and selecting the right geotextile for your specific needs, you can ensure that the material performs effectively for as long as possible.

To get started on your next project, consider sourcing high-quality materials from trusted suppliers. If you’re looking for an affordable option, you can buy geotextile from reputable manufacturers who offer a balance of cost and quality. For bulk orders or long-term projects, it’s also worth reaching out to a cheap geotextile manufacturer who can provide cost-effective solutions without compromising on material performance. By taking these steps, you’ll be well on your way to ensuring the durability and longevity of your geotextile installations.